Coal washing plant is a facility that washes coal of soil and rock, crush it into graded sized chunks, stockpiles grades preparing it for transport to market. During this whole process, equipment will suffering from serious abrasion problems, especially for the washing piping systems.

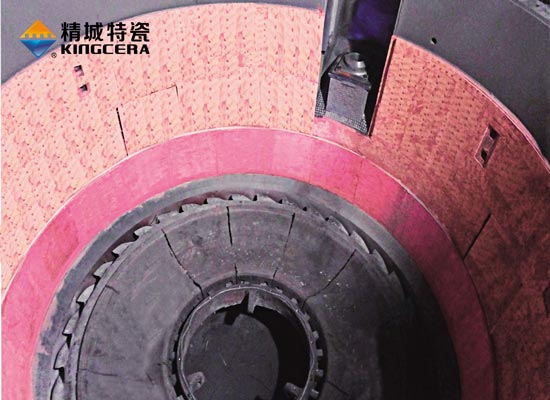

Recently, KINGCERA was invited to conduct a site measurement for a big coal washing plant in Shanxi Province. We have been supplying

ceramic lined pipes and elbows to them in the past 3 year. From their feedbacks, we know they are very satisfactory with the quality as the former pipes are still under working without any failures. This time they hope to make a whole optimization of the coal washing processing piping system.

It takes us 1 week to finish the measurement of this whole pipe line which exceeded to 200 meters. This optimization piping system contains elbows, straight through pipe and Tee-through. We advise the customer to apply fully lined ceramic tiles to the piping system. They will be either lined with 5mm thick or 9mm ceramic tiles according to different processing periods. This will greatly improve their production capacity and reduce down the maintenance time&repair costs.