In the beginning of this June ,Kingcera just finished our delivery for the DN300 95% alumina ceramic sleeve lined pipes ,bends and T pipes applied in mining slurry conveying system. It’s a very big step for Kingcera to develop the big diameter ceramic sleeve by using isostatic pressing which is one of the best pressing method to do the 95% alumina ceramic sleeves.

The big diameter ceramic sleeve is always a big problem for the ceramic tube manufacturers since it’s very difficult to control the deformation rate of the ceramic sleeve after it’s sintering .Also It will also need an advanced and big isostatic pressing machine to do this .So it will not only express the company’s production capability ,but company’s technology. Right now, Kingcera have owned both advantages which are

wear resistant ceramic pressing facilities and technologies.

We met some difficulties of course when we manufacturing the ceramic sleeves and we handled all the problems after the efforts of our research and engineering people .Also we created a very convenient installation machine to do the ceramic sleeve installation into the pipes since the sleeve is very big and heavy .After a month working ,we finished this 20’ container 95% alumina ceramic sleeve lined pipes ,T pipes and elbows and customers are also very appreciated about our rapid reaction and big efforts in this projects applied in the mining slurry conveying system.

After the inspection by our company’s QC people, we packed all the ceramic sleeve lined pipe fittings by 3 steel crates. According to the customers requirements, we painted the item No, Spool No and company name on the surface of the 95% alumina ceramic sleeve lined pipe fittings. What’s more ,to prevent the damaging of the flanges, we also used the plastic flange caps covered on the flanges to protect the pipe steel flanges. The customers are very appreciated it after I took the pictures to the them and gave us a highly praise about the quality and details’ control. We are also enjoying the accomplishment when the customers gave the positive recognition about our products and our services.

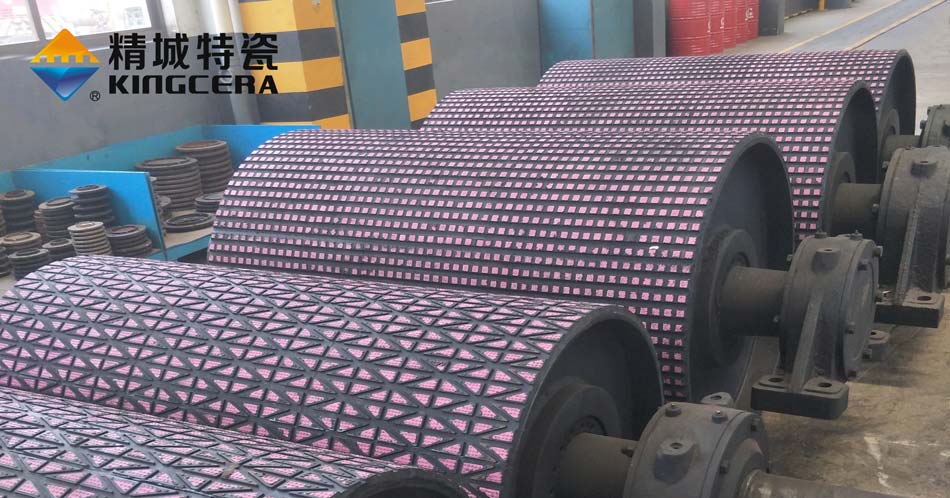

Later on,Kingcera’s engineers and workers summarized all the experiences we had during this project since this is very first time to do such big alumina ceramic sleeves. It showed Kingcera’s alumina ceramic tube products range to move a big step to another higher level in the wear resistant ceramic manufacturing. It will also help our other products range development like alumina ceramic wear liner lining chutes and hoppers ,small diameter ceramic sleeve lined pipe fittings ,ceramic tiles lining pipes, cyclones and ceramic laggings pulley.