In the end of March ,we finished our delivery for the DN600 welding ceramic tile lining pipes applied in coal-fired power plant within 20 days .The customers are very happy and appreciated for our efforts to finish this urgent project.

These pipes applied in the outlet of the coal mill in the power plant and suffered a very serious abrasion, impact and high temperature. Customers used the overlay hardfacing pipes to do the wear protection before ,but it can only use about 1-2 month to wear out .It’s a very big headache to do the maintenance and replacement all the time .After we received these information ,we provided this welding 95% alumina ceramic tile lining pipe solution rapidly and give the solution to the customers within one day. After discussion, they decided to have a try our custom solution. Before production, we met another issue is that the customer need it very urgently and they wish us to finish it within 20 days and catch up the closest shipment .

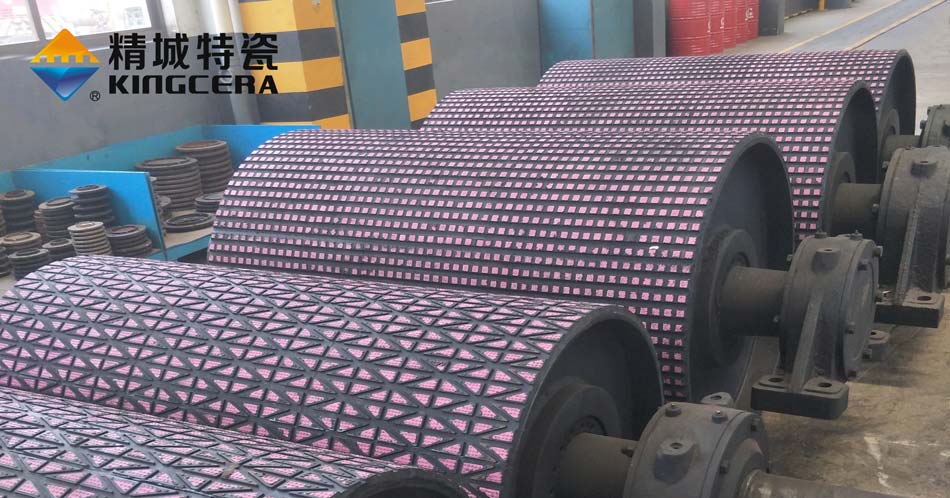

To ensure we can meet the quality and delivery requirements, we organized all the department to cooperate with each other and finished all the welding ceramic tile lined pipes based on the superior quality .

The customer arranged the quality inspectors once we finished all the products .During the inspection ,The inspectors analyzed the content of alumina, the hardness of the ceramic ,bonding strength of the adhesive, the outsize size, flanges size and packages etc. After the inspection ,the the quality inspector also gave us a high praise on our experienced installation and strict quality control.

After the inspection ,We also showed Kingcera’s laboratory to the quality inspector and they are shocked about our fully-equipped facilities .In Kingcera’s Lab ,you can find every testing machines in the lab for Vicker Hardnees ,Rockwell Hardness ,bending and bonding strength, compression strength ,fracture strength and so on for our

wear resistant ceramic linings.

As we always keep the quality and service in our mind ,we will not only provide our rapid and suitable solutions, but keep our quality as the solution designed .Thanks for the customer’s trust and looking forward to provide more solutions to all the customers applied in mining ,cement, power plant ,steel and sea port.