In steel production, every step is crucial, and the swing chute, as the core component of the blast furnace top equipment, plays a an important role. It is like a precise mixer, skillfully delivering iron ore, fuel, etc. into the material tank in strict proportions, ensuring the smooth progress of the iron making process. However, this process faces great challenges for the swing chute - the material flow is large and the impact is strong. It has been subjected to the continuous impact of hard materials such as ore and pellets falling from a high place for a long time, especially the bottom of the chute, where the wear and impact are particularly severe.

Faced with such harsh working conditions, how to effectively extend the lifetime of the swing chute and reduce downtime and maintenance time caused by wear has become a major problem for many steel plants. At this time, wear-resistant ceramic linings came into being, bringing a new solution to this problem.

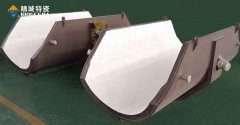

Ceramic lining of swing chute on the top of blast furnace

Kingcera improves the wear resistance of the swing chute by installing ceramic linings on the inner wall and bottom of the swing chute, reducing the direct impact , thereby protecting the substrate from damage and extending the lifetime of the equipment.

Kingcera mainly uses 95 alumina ceramics and 99 alumina ceramics in the anti-wear solution for the swing chute. Both materials have excellent wear resistance and corrosion resistance, but there are slight differences in performance. 99 alumina ceramics usually show more excellent wear resistance due to their higher purity. As for the shape and size, they are completely customized according to actual needs. Whether it is round, square or special-shaped design, it can perfectly fit the specific structure of the swing chute to achieve seamless protection.

It is particularly noteworthy that the thickness of the selected ceramics needs to be carefully considered in view of the huge impact force on the bottom of the swing chute of the steel plant. Generally speaking, a thickness of more than 70 mm is a basic requirement to ensure sufficient impact resistance. For extreme working conditions, you can also consider using more solid ZTA ceramics. This material not only has extremely high hardness, but also has good toughness. It can remain stable under heavy load impact, further improving the durability and safety of the chute.

Ceramic lined swing chute

The anti-wear concept of wear-resistant ceramic swing chute is not only used in steel plants, but also in cement plants, thermal power plants, mines and other heavy industrial fields. In different application scenarios, Kingcera will provide customized anti-wear design and installation services according to the specific working environment and wear characteristics. Whether it is for high temperature, high pressure or complex working conditions containing corrosive media, you can find a suitable wear-resistant ceramic solution to ensure that the equipment can operate efficiently and stably under harsh conditions.

(Original link:

https://www.fangmo.com/jishu/775.html; Steven He / Translated)