With the rapid development technology of semiconductor equipment , Kingcera recently reached a cooperation with a well-known semiconductor company in Jiangsu,which customized a batch of high-quality 997 alumina long ceramic plates. This long ceramic plate with its unique physical and chemical properties plays a vital role in the semiconductor manufacturing process.

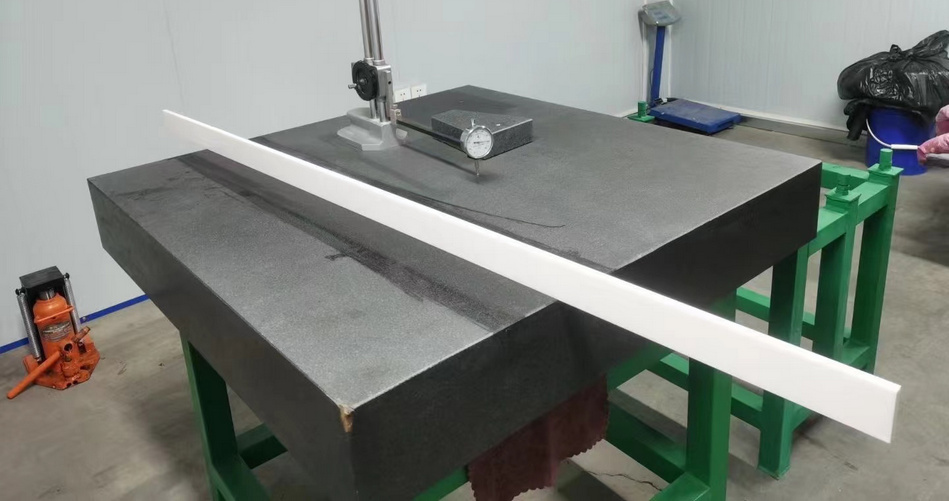

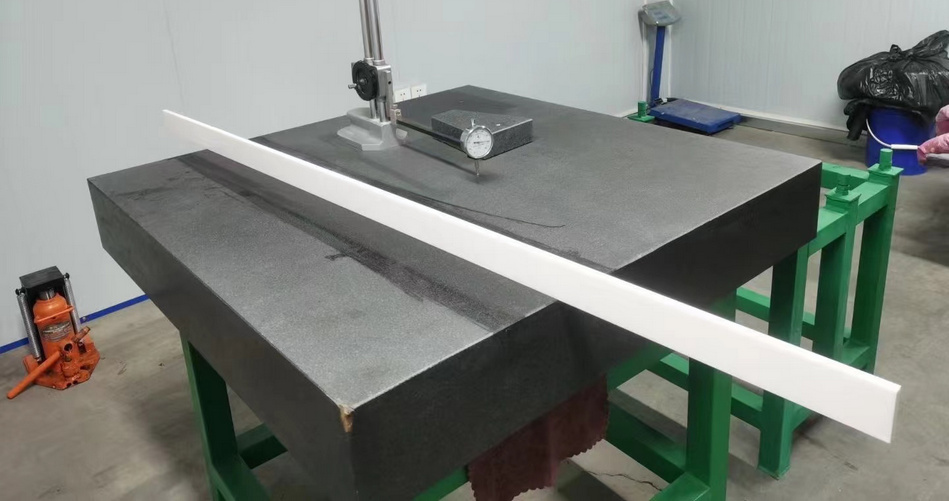

The 997 alumina long ceramic plates length is nearly 2 meters, width is about 0.5 meters, and the thickness is only 7 millimeters. Such ultra-thin dimensions not only require the material to have extremely high strength and toughness, but also need to be perfectly flat during the production process to avoid any damage to the delicate semiconductor components.In addition, the surface quality of the ceramic plate is also extremely critical. It must be smooth and flawless, with no scratches, no black spots, no burrs, flash edges, sharp edge chamfers, no chipping, and no bumps to meet the strict requirements of the semiconductor manufacturing process requirements.

In order to meet the stringent production requirements of the semiconductor industry, Kingcera has demonstrated its strong ceramic production and finishing capabilities. Kingcera was equipped with a lifting furnace of more than 2.4 meters and a large-tonnage isostatic press machine for 4 meters. These advanced equipment ensure the dimensional stability during the production process and the reliability of product quality.

In the finishing process, Kingcera has a series of professional equipment such as ceramic engraving machines, grinders, engraving and milling machines and ceramic testing equipment. These machines enable the fine machining of complex ceramic workpieces, ensuring that ceramic materials achieve precise size, shape, surface finish and performance requirements while maintaining hardness and strength.

This batch of customized alumina long ceramic plates are mainly used for insulation and wear protection in the semiconductor industry. In semiconductor manufacturing, precision components need to be processed and assembled in a highly clean, friction-free environment. 997 high-purity alumina ceramic long plate has become an ideal material in this process with its excellent insulation performance and anti-corrosion and wear resistance.

At present, Kingcera has successfully delivered some products and has been highly recognized by customers. Recently, this customer has placed an additional larger order, further proving that Kingcera’s technical advantages in the supply of high-end materials for the semiconductor industry.

With the vigorous development of the semiconductor industry and the continuous acceleration of technological innovation, the requirements for material performance have become increasingly stringent. Against this background, Kingcera has become a leader in the industry with more than three decades of experience in the production of ceramics. Kingcera not only introduced advanced production equipment, but also established a complete and mature production and processing system, and gathered a professional team with superb skills and rich experience.

Looking forward to the future, Kingcera will continue to increase investment in technology research and development and innovation, and is committed to supplying high-quality, high-performance ceramic products to high-end fields such as semiconductors, and contributing more power to the continued progress of the semiconductor industry and the equipment localization process .

(Original link:

https://www.fangmo.com/taoci/590.html)