Ⅰ. The reason and mechanism analysis of conveyor chute wear

In mining, steel, cement and other industrial production, conveyor chute as an important transportation device in material conveying system is mostly used to convey ore, coking coal, lime and other materials. The common characteristics of chutes are large material impact, serious wear and high working temperature. From the point of view of the tribological system, the wear failure of the chute is dominated by abrasive wear and corrosive wear, and adhesive wear may occur under heavy load.

Therefore, in order to improve the overall life of the chute, measures must be taken from the materials and manufacturing process of the chute, structural optimization design, surface treatment, correct use and maintenance. On the one hand, it is necessary to improve the working conditions to reduce wear, and on the other hand, it is to improve the hardness and wear resistance of the surface of the conveyor chute chain by installing the wear chute liner plate.

Ⅱ. The analysis of material, performance and service life of conveyor chute liner

1, High manganese steel lining board:

Advantages: excellent toughness, rapid surface hardening phenomenon under strong impact or extrusion conditions, and the surface hardening layer has good wear resistance performance.

Disadvantages: Easy to plastic deformation, the wear resistance is general under the no impact condition .

2, High chromium cast iron wear liner:

Cast iron is commonly used in engineering wear problems, which is divided into three types according to its carbon content: gray cast iron, white cast iron and hemp cast iron.

Advantages: high hardness (HRA70-80), good wear resistance.

Disadvantages: It couldn’t be cut and has welding difficulties. Moreover, it is brittle and unable to withstand heavy impact load.

3, New alloy steel wear liner:

The hardness and service life of the new alloy steel wear liner are better than cast iron liner, which is mainly composed of chromium, nickel and molybdenum. From the content of alloying elements, it can be divided into low alloy, medium alloy and high alloy wear resistant steel; and from the different structure, it can be divided into austenite, bainite, martensitic wear resistant steel.

Advantages: strong plasticity, good mechanical properties, rust and corrosion prevention; The toughness and hardness can be changed by adjusting the alloy proportion and forging process.

Disadvantages: However, the hardness and weldability of alloy materials restrict each other, high hardness weldability will become poor, so it’s difficult to install. Therefore, the hardness of the general alloy material liner is difficult to exceed HRA60, and the usage is limited in the heavy wear industry.

4, Basalt wear liner:

Basalt is a kind of processed silicate crystalline materials, and the main raw material is natural rock (basalt, diabase and other basic rock, as well as shale) or industrial slag (blast furnace slag, steel slag, copper slag, chromium slag, ferroalloy slag, etc.). It can be divided into ordinary basalt liner and microcrystalline basalt liner according to the different production process and formula.

Advantages: Relatively speaking, the production process is simple. It has high hardness with low price. It’s wear-resistant performance is more than ten times better than steel liner and cast iron wear liner.

Disadvantages: poor plasticity, difficult cutting. And the toughness and impact resistance are relatively poor. Therefore, it is relatively rare in today's industrial plant.

5, Ultra-high molecular polyethylene wear liner:

Advantages: Polyethylene polymer material has good wear resistance, good sliding performance, low friction coefficient, corrosion resistance insulation, light texture and easy processing. In addition, it has the characteristics of good shock absorption and silencing, which can reduce the noise and play a role in environmental protection. The general thickness is 10~30mm.

Disadvantages:low surface hardness and thermal deformation temperature, poor bending strength and creep performance, so it is unable to withstand large impact and limited in high temperature and heavy wear condition.

6, Wear-resistant ceramic liner:

The chute wear-resistant ceramic liner is currently the most widely used chute liner material with good effect. It uses alumina as the main raw material, which is converted into α— Alumina.

Advantages: high hardness (HRA88), second only to diamond. Density is greater than or equal to 3.9g/cm3; Flexural strength is greater than 350MPA; impact toughness is greater than or equal to 2.2J/cm², and its modulus of elasticity is greater than 317GPA. ZTA ceramics are made by adding zirconia. Afterwards, it can also have strong impact resistance, and in heavy wear conditions, the service life can reach more than 10 times that of manganese steel liner.

Ceramic liner plate installed in mining chute

Ceramic liner plate installed in mining chute

Ⅲ. KINGCERA chute anti-wear solution

Mine chute or coal feeder chute often uses manganese steel liner or waste ball mill liner as anti-wear material. But the wear is serious and need to be frequently replaced. Some even less than a week need to be replaced, which seriously affects labor efficiency and safety production.

KINGCERA's high temperature impact-resistant wear-resistant ceramic chute liner can replace the manganese steel liner, which can fundamentally solve the wear problem. The high temperature impact-resistant wear liner is welded in the equipment by stud welding of toughened ultra-thick ZTA, so as to form a strong anti-wear layer. Some spherical bulges can be designed on the lining to further enhance its impact resistance. For ease of installation and replacement, the ceramic liner can be mounted on the steel plate and then mounted on the equipment by welding or countersunk bolts.

According to the feedback of many cement plants, steel plants, mines, the wear-resistant ceramic chute liner can prolong the service life of equipment by 10-20 times than manganese steel liner, greatly saving maintenance time and reducing workers’ labor intensity.

Stud-welding wear ceramic chute liner

Stud-welding wear ceramic chute liner

Ⅳ. Installation of wear ceramic liner

1, directly adhesive paste: use room temperature or high temperature strong inorganic adhesive paste to install. It is easy to install and suitable for small impact with the working temperature below 200℃.

2. stud welding: it can be used for high temperature materials and materials with high impact force. The mechanical self-locking force and inorganic adhesive can ensure that the liner does not fall off;

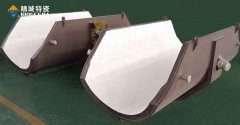

3. prefabricated ceramic liner installation: ceramic need to be installed on the steel plate firstly to make a two-in-one ceramic liner (ceramic + steel plate), or three-in-one ceramic liner (ceramic + rubber + steel plate), and then through welding or countersunk bolts to install it on the equipment, which are easy to repair and replace.

Installation of wear ceramic in blanking chute (three-in-one liner + stud welding)

Installation of wear ceramic in blanking chute (three-in-one liner + stud welding)

Ⅴ. characteristics of KINGCERA’s ceramic chute liner

1. long service life: improve the service life of more than 20 times;

2. anti-falling: inorganic adhesive, stud welding, dislocation bonding and other unique processes to ensure that the ceramics do not fall off;

3. impact resistance: the toughened ultra-thick wear-resistant ceramics significantly improves the impact toughness of the chute liner;

4. high temperature resistance: it can be used in 350℃ working temperature.

Wear ceramic mining chute

Wear ceramic mining chute

Three-in-one wear ceramic chute liner

Three-in-one wear ceramic chute liner

Chute wearing plate | chute ceramic liner

Chute wearing plate | chute ceramic liner