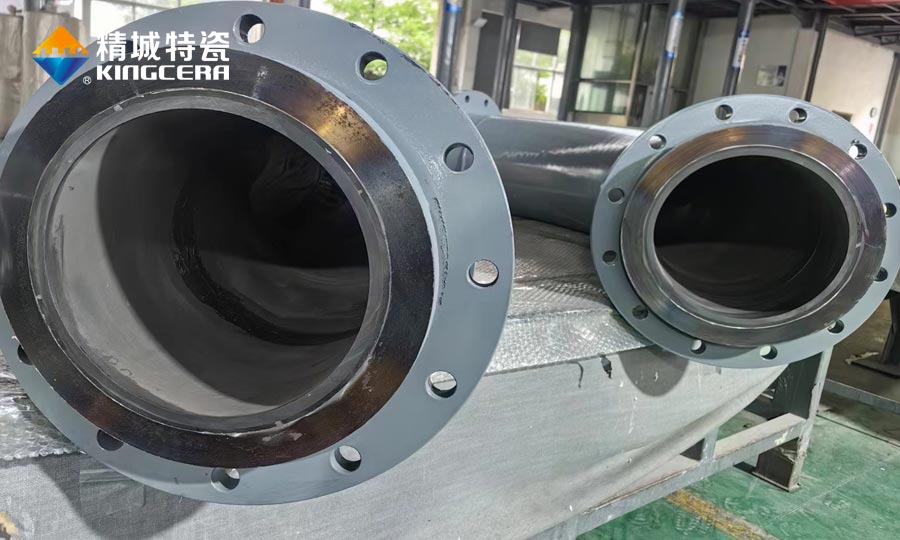

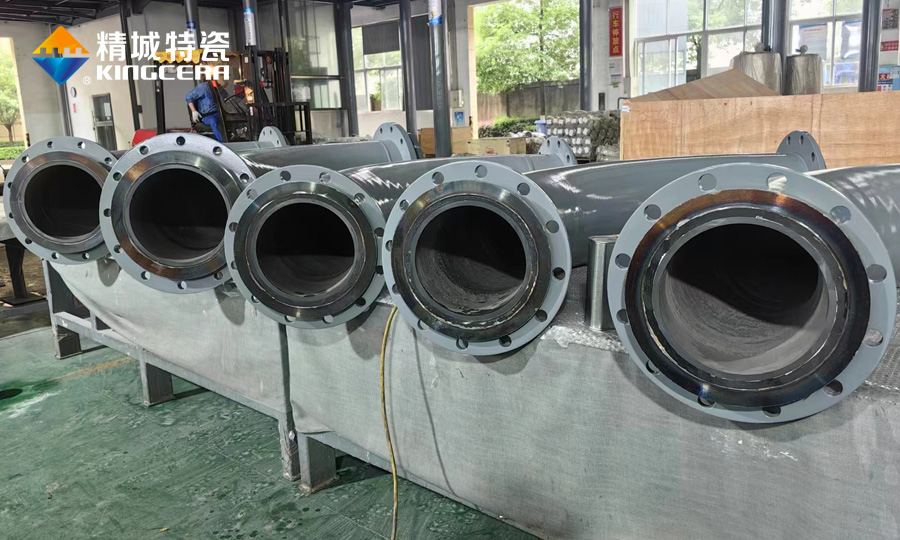

Sintering as a whole RBSIC ceramic tube or ceramic sleeve/ceramic segment,and then assemble it into the carbon steel pipe/stainless steel pipe with our high-strength-resistant epoxy adhesive. The RBSIC ceramic sleeve lined pipe fittings has applied a lot in the mining slurry,slag and mud conveying ,like mining slurry pipe,mining dust removing pipe ,mining slag conveying pipe ,elbows and T pipes.

Recently,Hunan Kingcera finished a RBSIC lined pipe fittings including pipe and elbows for one of the biggest mineral processing company.They tried a small trail orders with the RBSIC lining for wear protection applied in the slurry conveying system for the sliding and wear protection before and it worked very well after 2 years.

Because of our superior quality ,right now we received more repeat orders and our wear resistant (92%/95%/SIC)ceramic sleeve lined pipe have enjoyed a very good reputation in Australian mining industry.It saved lots of shutdown time ,but increased the production ability.

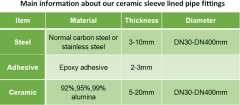

Main information about our ceramic sleeve lined pipe fittings

|

Item |

Material |

Thickness |

Diameter |

|

Steel |

Normal carbon steel or stainless steel |

3-12mm |

DN30-DN500mm |

|

Adhesive |

Epoxy adhesive |

3-5mm |

|

|

Ceramic |

92%,95%,99% alumina/RBSIC,SSIC |

5-25mm |

DN30-DN500mm |

Features

1. Superior wear resistance

3.corrosion&acid resistance

4.Smooth inner wall

5. Easy installation

6. Saved maintenance time and expenditures

7.Longer service lifetime