As heavy bulk materials pass from station to station in a minerals processing plant, processing equipment is stretched to the limits of its capabilities. The wear rate of components, typically in chutes and hoppers is very high. The cost of replacing worn down consumables makes up a substantial proportion of the total maintenance expenses, so anything that can be done to reduce wear and increase equipment lifetime will have a significant impact on operating cost. The right choice of wear protection can contribute significantly to reducing maintenance costs and equipment downtime.

With the strong demand from end user to reduce maintenance cost and increase production, this has resulted in the need for wear products to perform for longer periods. Using lighter and tougher wear resistance materials is driving a trend towards.

Traditional metallic wear liners are heavy – up to 40 percent heavier than ceramic. The hardest metals are particularly expensive and difficult to work with. Furthermore, they have significant limitations when operating in either of the temperature extremes. While hardness is reduced at higher temperatures, impact strength is reduced at lower temperatures.

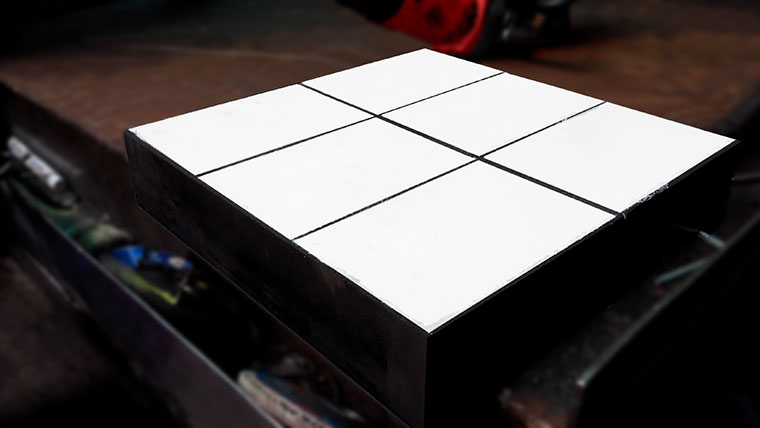

Ceramic wear liners is more lighter and durable than metallic wear liners.

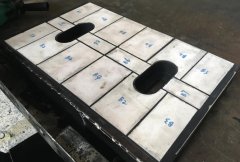

Ceramic wear liners comprise of ceramic tiles, moulded in a high tensile strength natural rubber matrix, and mounted on steel backing plates. All rubber ceramic liners are hot vulcanized together using specialized equipment which provides a bond strength that exceeds the tensile strength of the natural rubber matrix. As a result the ceramics will remain in the rubber matrix, offering consistent wear protection across the entire life of the liner.

In one Iron and Steel plant, Kingcera ceramic wear liner were installed in a conveyor discharge chute downline from the secondary crusher unit where the material drops five meters from one conveyor belt down to another one. The hardness of the iron ore is approximately 7 on the Mohs scale. After installation, the plant has until now operated for 329 days (and still running), and it operated at full production of 800 mtph with lump sizes of up to 200mm in diameter. This was a big step up from the previous liner, which had lasted less than eight weeks on average.