TiC based steel bonded cemented carbide rod provides new composite solution for all kinds high manganese or low alloy wear parts’wear resistance performance on crushing system in the field of mining,cement, steel making.

Almost 10 years ago, TiC-based bonded cemented carbide rods was mainly used on crusher hammer head in the process of limestone and clinker crushing in cement plants. Compared to ordinary high-Mn hammer head, service life will be 1.7-2.3times longer.

In recent years, there are below new application trends in the market:

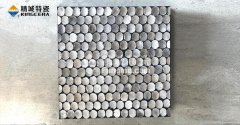

1. Replace WC-based cement carbide stud on HPGR (high pressure grinding roller) roller: high cost effectiveness is reflected in its good wear resistance performance, nice unit cost and lower density. Some manufacturers combine casting and welding to make this kind of composite HPGR roller, some in mechanical way by using centerless ground tic rods;

2.Play as wear liner in heavy shock limited space: all wear liner plays good resistance at certain thickness, in some limited space, like ship unloader hopper, secondary crushing hopper, abrasion loss mainly caused by heavy impact by big ore. Similar to high-Mn wear parts, tic rods are also have the performance of “working hardening”, under heavy shock , the hardness will higher. Furthermore, tic rods made by powder metallurgy method through the designing and optimizing of forming and liquid phase sintering technology. At the same unit space, higher compactness, smaller grain size, more wear-resistant grains quantity, then better wear resistant performance .

Anyone who is seeking composite wear parts, please contact us to get more details.

Besides above items, there are more applications that tic based steel bonded cemented carbide products could do,such as guide roller for rod mill in steel making plants. Will share more then.